EGSB --- Expanded Granular Sludge Blanket Reactor

Anaerobic microorganism treatment is an indispensable treatment section in the current high concentration organic wastewater sewage water treatment process. It is better that aerobic microorganism treatment not only has low energy consumption, but also can produce biogas as a secondary use of energy. The higher the anaerobic reaction volume load is, the higher the oxygen reaction is, and the lower the investment is for treating the same amount of COD anaerobic reaction.

At present, the commonly used anaerobic treatment processes include:

UASB --- Up-flow Anaerobic Sludge Bed/Blanket

EGSB --- Expanded Granular Sludge Blanket Reactor

CSTR --- Continuous Stirred Tank Reactor

IC --- Internal Circulation Anaerobic Reactor

ABR --- Anaerobic Baffled Reactor

UBF --- Upflow Sludge Bed Filter

AF --- Anaerobic Biofilter

AFBR --- Anaerobic Fluidized Bed Reactor

USSB --- Upflow Staged Sludge Bed

AAFEB --- Anaerobic Attached microbial Film Expanded Bed

USR --- Upflow solid anaerobic reactor

PPR --- Plug Flow Reactor

Two-phase Anaerobic Reactor

EGSB --- Expanded Granular Sludge Blanket Reactor

EGSB,named as Expanded Granular Sludge Blanket Reactor, is the third generation anaerobic reactor.

Principle of EGSB

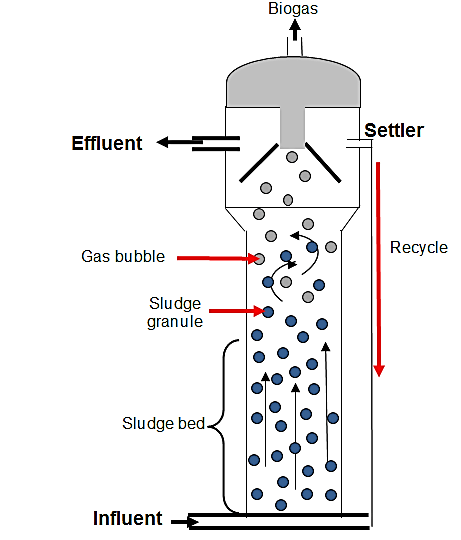

Its structure is similar to that of UASB reactor, which can be divided into inlet water distribution system, reaction zone, three-phase separation zone and outlet channel system.Different from UASB reactor, EGSB reactor is equipped with a special effluent return system.

EGSB anaerobic reactor is a new type of anaerobic reactor after UASB. It is a complete system composed of water distributor, three-phase separator, gas collecting chamber and external water inlet system. The organics of wastewater entering EGSB anaerobic reactor through sewage pump fully contact with the sludge at the bottom of anaerobic tank, and most of them are treated and absorbed. High hydraulic load and high gas load make the sludge and organic matter fully mixed, the sludge is in full expansion state, the mass transfer rate is high, and the anaerobic reaction rate and organic load are greatly improved. The generated biogas rises to the top and passes through three-phase separator to separate sludge, sewage and biogas. According to the actual operation, the removal rate of organic matters by EGSB anaerobic reactor is up to 85% and the operation is stable, and the effluent is stable.

The EGSB reactor is generally cylindrical tower, which is characterized by a large height diameter ratio, generally up to 3~5, and the reactor height of the production unit can reach 15~20 meters. The expanded bed of granular sludge improves the contact between organics and microorganisms in wastewater, strengthens the mass transfer effect, improves the biochemical reaction speed of the reactor, thus greatly improving the treatment efficiency of the reactor.

Characteristics of EGSB

Expanded Granular Sludge Bed (EGSB) is the third generation super efficient anaerobic reactor developed on the basis of the research results of upflow anaerobic Sludge Bed (UASB) reactor. In addition to all the characteristics of UASB reactor, this type of reactor also has the following characteristics,

1.High liquid surface rising velocity and COD removal load;

2.The particle size of anaerobic sludge is large, and the reactor has strong shock load resistance;

3.The reactor is of tower structure design, with high height diameter ratio and small floor area;

4.It can be used to treat wastewater with high SS content and toxicity to microorganisms.

5.It is mainly used for treatment of high concentration organic wastewater.

#QDEVU #WATERTREATMENT #WASTEWATERTREATMENT #SEWAGETREATMENT #SEWAGEWATERTREATMENT #BIOLOGICALTREATMENT #ANAEROBICPORCESS

Visit www.evuchina.com for more informations!