AF --- Anaerobic Biofilter

Anaerobic microorganism treatment is an indispensable treatment section in the current high concentration organic wastewater sewage water treatment process. It is better that aerobic microorganism treatment not only has low energy consumption, but also can produce biogas as a secondary use of energy. The higher the anaerobic reaction volume load is, the higher the oxygen reaction is, and the lower the investment is for treating the same amount of COD anaerobic reaction.

At present, the commonly used anaerobic treatment processes include:

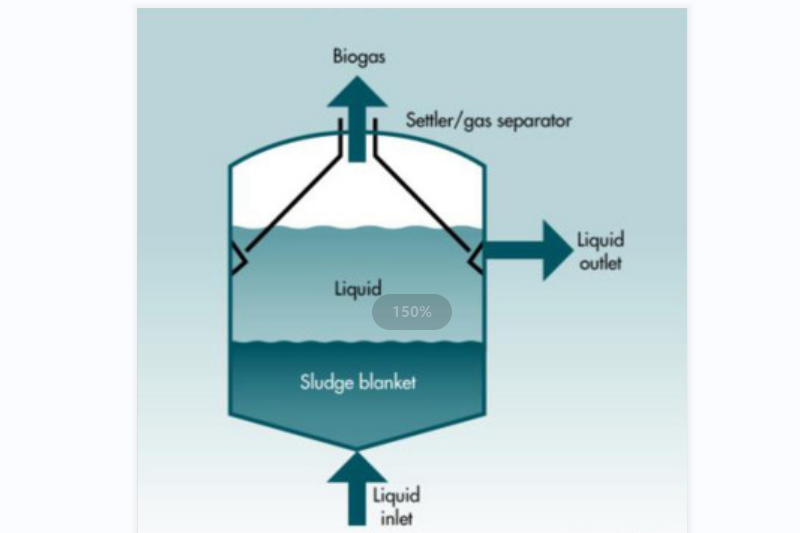

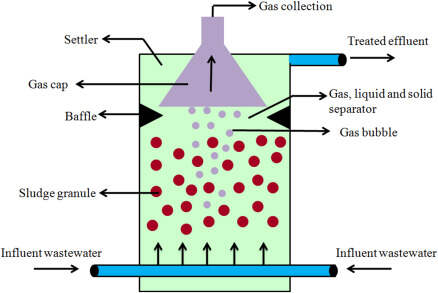

UASB --- Up-flow Anaerobic Sludge Bed/Blanket

EGSB --- Expanded Granular Sludge Blanket Reactor

CSTR --- Continuous Stirred Tank Reactor

IC --- Internal Circulation Anaerobic Reactor

ABR --- Anaerobic Baffled Reactor

UBF --- Upflow Sludge Bed Filter

AF --- Anaerobic Biofilter

AFBR --- Anaerobic Fluidized Bed Reactor

USSB --- Upflow Staged Sludge Bed

AAFEB --- Anaerobic Attached microbial Film Expanded Bed

USR --- Upflow solid anaerobic reactor

PPR --- Plug Flow Reactor

Two-phase Anaerobic Reactor

AF --- Anaerobic Biofilter

AF is short for Anaerobic Biofilter. This process is developed on the basis of traditional anaerobic activated sludge process.

Anaerobic bio-filter is an anaerobic bioreactor filled with microbial carrier. Some anaerobic microorganisms adhere to and grow on the filter material to form an anaerobic biofilm, and some grow in suspension between the gaps of the filter material. When the sewage flows through the filter material hung with biofilm, the organic matter in the water diffuses to the surface of biofilm, and is degraded and converted into biogas by microorganisms in the biofilm. The purified water is discharged to the outside of the pool through drainage equipment, and the generated biogas is collected and used.

Working Principle of AF

The AF reactor consists of five parts, namely, the Water Distribution System at the bottom of the tank, the Sludge Layer between the water distribution system at the bottom of the tank and the filter material layer, the Biological Filler, the Water Make-up System at the surface of the tank, and the Biogas Collection System.

In AF, the retention of anaerobic sludge is accomplished in two ways: first, bacteria form biofilm on the surface of fixed filler; The second is to form bacterial aggregates in the space of the reactor.

In AF, water enters from the bottom of the reactor. After being uniformly arranged through the water distribution system at the bottom of the tank, the wastewater passes through the suspended sludge layer and the biological filter material layer in turn, and the organic matter contacts with the sludge and the microorganism on the biofilm, and then is digested. The water is discharged evenly from the outlet water make-up system on the pool surface and then enters the next level of processor. Anaerobic biological filter can be divided into up-flow anaerobic filter and down-flow anaerobic filter according to the flow direction.

Advantages of AF

1.The treatment capacity is higher than that of ordinary digesters

2.High biomass concentration can obtain high organic load

3.No special mixing equipment is required, the device is simple, and the energy consumption of the process itself is low

4.The microbial body has a long residence time and strong resistance to shock load

5.No need for backflow sludge, easy operation and management

6.The operation can maintain greater stability in the case of large changes in the treatment water volume and load

Compared with the traditional anaerobic biological treatment structures and other new anaerobic biological reactors, the advantages of the anaerobic biological filter are:

High concentration of biological solids, so it can obtain higher organic load.

The microbial solid retention time is long, which can shorten the hydraulic retention time, and the impact load resistance is also high.

The starting time is short, and it is easier to restart after stopping operation.

The amount of excess sludge generated is very small, and there is no need for sludge reflux and excess sludge treatment facilities, which is high investment and convenient for operation and management.

Its operation can maintain greater stability in the case of large changes in the treatment water volume and load.

After practical application, there is no need for biogas treatment system when treating low concentration sewage.

#QDEVU #WATERTREATMENT #WASTEWATERTREATMENT #SEWAGETREATMENT #SEWAGEWATERTREATMENT #BIOLOGICALTREATMENT #ANAEROBICPORCESS

Visit www.evuchina.com for more information